How To Build A Concrete Slab For A Garage

Constructing a concrete slab for a garage requires careful planning and execution. This guide provides a comprehensive overview of the process, from site preparation to concrete finishing. Following these steps will help ensure a durable and stable foundation for your garage.

1. Planning and Permits

Before starting any construction, thoroughly plan the project. This includes determining the size and location of the garage slab, considering local building codes and obtaining necessary permits. Accurate measurements are crucial for calculating material quantities and ensuring the slab fits the intended structure. Check with local authorities regarding zoning regulations, setbacks, and any specific requirements for garage foundations.

2. Site Preparation and Excavation

Proper site preparation is essential for a level and stable slab. Begin by clearing the area of vegetation, rocks, and debris. Mark the perimeter of the slab using stakes and string lines, ensuring accurate dimensions and square corners. Excavate the area to the desired depth, typically 4-6 inches for a garage slab, depending on soil conditions and local building codes. A compacted gravel base, usually 4 inches deep, should be added and thoroughly compacted to provide a stable sub-base for the concrete.

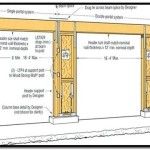

3. Formwork and Reinforcement

Construct formwork around the perimeter of the excavated area using 2x4 lumber or other suitable materials. Ensure the forms are straight, level, and securely braced to prevent movement during the concrete pour. Reinforcement is crucial for strength and crack resistance. Place a grid of steel rebar within the formwork, supported by chairs or bricks to keep it elevated within the concrete. The spacing of the rebar will depend on the anticipated load and local building codes.

4. Vapor Barrier Installation

A vapor barrier, typically a sheet of polyethylene plastic, should be placed over the compacted gravel base before pouring the concrete. This barrier prevents moisture from migrating up through the concrete, which can lead to cracking and other issues. Overlap the edges of the vapor barrier by several inches and seal the seams with tape to ensure a continuous barrier.

5. Concrete Placement and Finishing

Order ready-mix concrete from a reputable supplier, ensuring the mix is appropriate for a garage slab. Once the concrete arrives, pour it evenly within the formwork, spreading it with shovels and rakes. Consolidate the concrete using a vibrator to remove air pockets and ensure proper settlement around the rebar. After pouring, the surface needs to be leveled using a screed board and smoothed with a bull float. This creates a flat and even surface. Allow the concrete to cure slightly before applying a broom finish for a non-slip surface.

6. Curing and Protection

Proper curing is crucial for the concrete to achieve its full strength and durability. Keep the slab moist for at least seven days after pouring. This can be achieved by covering the slab with plastic sheeting, wet burlap, or by spraying it with water regularly. Avoid letting the surface dry out completely during this period. Protect the curing concrete from extreme temperatures, both hot and cold, as these can negatively impact the curing process.

7. Control Joints

Control joints are intentionally weakened lines created in the concrete to control cracking. These joints encourage cracking to occur along these predetermined lines rather than randomly across the slab. Control joints can be created by sawing them into the concrete after it has partially cured or by inserting pre-formed joint material during the pouring process. The spacing of control joints depends on the slab’s size and thickness and should be determined based on local building codes and best practices.

Building a concrete garage slab requires a methodical approach and attention to detail. By following these steps and consulting with local professionals, you can create a durable and long-lasting foundation for your garage.

24 X Garage Build Footing Dig Monolithic Slab Pour

Pouring A Concrete Slab For Metal Carports

How To Pour A Concrete Slab Diy Family Handyman

How To Manufacture A Garage Pad Easily

How To Build And Pour A Foundation For Garage Diy

How To Pour A Concrete Slab Diy Family Handyman

How To Build A Garage Ground Work And Concrete Pad

How To Pour A Concrete Slab For Your New Metal Building Structure

How To Pour A Concrete Slab For Your New Metal Building Structure

Diy Concrete Foundation For A Garage Or Shed With Curb Wall

Related Posts