Creating The Perfect Truck Garage Plans In Revit 2025 Horosc Tamilnilam

Revit 2025 offers a powerful platform for designing and visualizing truck garages, catering to a wide range of needs from personal use to commercial fleet maintenance. The Horosc Tamilnilam aspect, although seemingly disconnected, can be incorporated as a conceptual element by subtly influencing design choices based on principles of Vastu Shastra or similar spatial harmony concepts to potentially enhance the user experience within the garage. This article outlines the key steps involved in creating comprehensive and functional truck garage plans within Revit 2025, touching upon crucial design considerations and emphasizing best practices.

The design process begins with a thorough understanding of the garage's intended purpose. Will it primarily house a single truck, or will it accommodate a fleet? Will it serve purely for storage, or will it incorporate maintenance and repair facilities? Answering these questions directly informs the required square footage, door dimensions, equipment needs, and overall layout. Ignoring these preliminary considerations can lead to significant design flaws and costly revisions later in the project timeline.

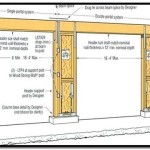

Before launching Revit 2025, gather all necessary data. This includes the dimensions of the largest truck intended to be housed in the garage, along with any anticipated future vehicle upgrades. Consider the turning radius required for maneuvering within the space, as well as clearances for opening doors and performing maintenance tasks. Gathering this information upfront ensures that the Revit model accurately reflects the real-world constraints of the garage's operation.

Once the preliminary information is gathered, the design process in Revit 2025 can commence. The first step involves establishing the project's base units and setting up the levels. Consistent use of appropriate units (e.g., feet and inches, meters) is critical for accurate modeling and documentation. Levels should be defined to represent the floor, roof, and any intermediate levels, such as mezzanines or equipment platforms. The placement and number of levels will directly influence the vertical design and spatial organization of the garage.

Walls are the next fundamental element to define. Revit 2025 offers a variety of wall types, from basic generic walls to pre-defined assemblies that incorporate insulation, cladding, and structural layers. Selecting the appropriate wall type depends on factors such as climate, budget, and aesthetic preferences. Accurately defining the wall thicknesses and material properties ensures that the Revit model accurately represents the thermal performance and structural integrity of the garage.

Doors are a critical element in any truck garage design. Revit 2025 offers a wide range of door families, including overhead doors, sectional doors, and sliding doors, each with its own unique operating characteristics and dimensional requirements. Selecting the appropriate door type depends on factors such as the size of the trucks, the frequency of access, and the available headroom. It is crucial to ensure that the door openings are adequately sized to accommodate the largest truck intended to use the garage.

Once the basic structure is established, attention should turn to detailing the interior layout. This includes the placement of equipment, storage areas, and work spaces. Consider the flow of traffic within the garage, ensuring that there is adequate space for maneuvering equipment and performing maintenance tasks. Proper lighting is also essential for a safe and efficient work environment. Revit 2025 allows for the placement of light fixtures and the simulation of lighting levels to optimize the design.

Plumbing and electrical systems are integral components of any functional truck garage. Revit 2025 provides tools for modeling and coordinating these systems, ensuring that they are properly sized and routed. Consider the location of water lines, sewer lines, and electrical panels. Ensure that there are adequate outlets and water connections for powering tools and equipment. Proper planning of these systems is crucial for the safe and efficient operation of the garage.

Optimizing Space and Functionality

Space optimization is paramount in truck garage design. Consider incorporating vertical storage solutions to maximize the use of available space. Mezzanines can provide additional storage or office space without expanding the building's footprint. Strategic placement of equipment and tools can minimize clutter and improve workflow. Carefully consider the placement of workbenches, tool chests, and parts storage to create an efficient and organized work environment.

The incorporation of specialized equipment is a key consideration in many truck garage designs. This may include lifts, cranes, air compressors, welding equipment, and diagnostic tools. Revit 2025 allows for the placement of these items and the simulation of their operation. Ensure that there is adequate space for maneuvering equipment and performing maintenance tasks around these specialized items. Consider the power requirements of each piece of equipment and provide adequate electrical connections.

Natural light and ventilation are important considerations for creating a comfortable and healthy work environment. Consider incorporating windows and skylights to maximize natural light penetration. Proper ventilation is essential for removing exhaust fumes and maintaining air quality. Revit 2025 allows for the simulation of air flow and the optimization of ventilation systems. The placement of ventilation fans and exhaust systems should be carefully considered to ensure effective removal of pollutants.

Integrating Structural and MEP Systems

Structural integrity is a critical aspect of truck garage design. Revit 2025 provides tools for modeling and analyzing the structural performance of the building. Consider the load-bearing capacity of the walls, roof, and floor. Ensure that the structure is adequately reinforced to withstand the weight of the trucks and equipment. Collaborate with a structural engineer to ensure that the design meets all applicable building codes and standards.

Mechanical, electrical, and plumbing (MEP) systems are integral components of any functional truck garage. Revit 2025 provides tools for modeling and coordinating these systems. Consider the location of HVAC systems, electrical panels, and plumbing fixtures. Ensure that the systems are properly sized to meet the demands of the garage. Coordinate the placement of these systems with the structural elements to avoid conflicts.

Fire safety is a paramount concern in truck garage design. Revit 2025 allows for the placement of fire suppression systems, such as sprinklers and fire extinguishers. Consider the placement of fire-resistant materials and fire-rated doors. Ensure that the design complies with all applicable fire safety codes and standards. Consult with a fire protection engineer to ensure that the design provides adequate fire safety protection.

Leveraging Revit 2025 Features and Collaboration

Revit 2025 offers several features that can streamline the truck garage design process. Parametric modeling allows for the creation of intelligent building components that can be easily modified. Worksharing allows multiple users to collaborate on the same Revit model simultaneously. Clash detection helps to identify and resolve conflicts between different systems. Utilizing these features can significantly improve the efficiency and accuracy of the design process.

Collaboration is essential for successful truck garage design projects. Share the Revit model with other stakeholders, such as clients, contractors, and engineers. Use Revit Server or BIM 360 to facilitate collaboration and communication. Conduct regular design reviews to identify and resolve issues early in the process. Effective communication and collaboration are crucial for ensuring that the design meets the needs of all stakeholders.

The integration of Horosc Tamilnilam principles, even in a subtle manner, can potentially enhance the overall user experience of the truck garage. This could involve aligning the orientation of the garage with auspicious directions, incorporating specific colors or materials, or ensuring that the layout promotes a sense of balance and harmony. While these considerations may not be directly related to the functional requirements of the garage, they can contribute to a more positive and uplifting work environment.

Finally, the creation of detailed documentation is an essential part of the Revit 2025 workflow. This includes creating floor plans, elevations, sections, and schedules. Ensure that all dimensions, annotations, and tags are accurate and legible. Create a comprehensive set of construction documents that can be used by contractors to build the garage. Proper documentation is crucial for ensuring that the garage is built according to the design specifications.

Top Elevation Architectural Designers In Thiruvananthapuram Near Me Justdial

Top Elevation Architectural Designers In Bagalkot Navanagar Near Me Justdial

Top Revit Structural Drafting Services In Chennai Near Me Justdial

Another Travel Guide

Top Interior Architects In Sullurpet Best Designers Justdial

Dundonald St Proposal On The Hot Seat At Tuesday Meeting Barrie News

Hướng Dẫn đặt 2 Mặt Cắt Trong Sketchup

ว ธ ปร บจ ด Start Point สำหร บงานป กระเบ อง ใน Revit ทำย งไง คล ปน ม เคล ดล บคร บ Autodesk Arhcitecture Architectural Architecturedesign สถาป ตย สถาปน ก Draftman Synergysoft

Dundonald St Proposal On The Hot Seat At Tuesday Meeting Barrie News

Worksheet 2 Cash Flow Statement Npv Calculation Ucl Brits Cell Therapy Project Planning And Valuation Tool

Related Posts